CNC Machining Aluminum

Providing custom precision CNC machined aluminum parts for a variety of industries.

Expert Brass CNC Machining Service

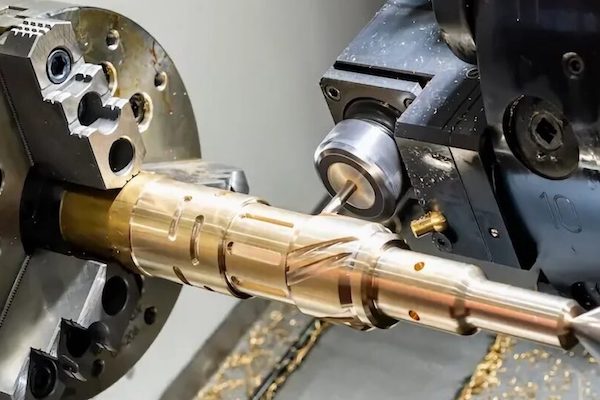

RALLY offers robust brass CNC machining capabilities backed by extensive experience, delivering customized solutions tailored to your requirements. You can select from various brass grades to suit your specific needs.

Equipped with a range of advanced CNC machining center and CNC lathes, we are prepared to meet all your brass CNC machining demands, ensuring top-quality parts with quick turnaround times.

CNC Brass Machined Parts

Our facility offers a full range of CNC machining services focused on brass components. We work with top-grade brass C360, which is perfect for products requiring high strength, outstanding corrosion resistance, excellent electrical conductivity, and low friction. Our advanced equipment, including diverse CNC mills and turning centers, enables us to manufacture both simple, “as-machined” items and complex designs with strict tolerances. Clients can choose from up to six post-machining treatments such as sandblasting, powder coating, smooth finishing, and polishing to improve the appearance and performance of the final products.

- Bushing, Gear, Valve Body

- Heat Sinks, Nozzles

- Knobs and Handles

- Shaft Components

- Electrical Connectors

- Screws and Fasteners

- Fixtures and Fittings

- Pump and Compressor Parts

Brass Parts Manufacturer In China

As a leading brass parts manufacturer in China, we specialize in precision CNC machining to produce high quality brass parts. Our expertise spans a wide range of industries, including automotive, aerospace, and electronics, where the need for durable and precision parts is critical. We utilize advanced CNC technology and a variety of brass alloys, such as C36000 and C38500, to produce functional and aesthetically pleasing parts.

Our machining capabilities include turning, milling, and drilling to handle projects ranging from simple to complex geometries. We also offer a variety of finishing options, such as plating and polishing, to enhance the durability and appearance of your products. Our commitment to quality and customer satisfaction ensures that we meet specific industry standards and customer expectations.

CNC Machining Brass Available Materials

Brass is a popular material for CNC machining due to its machinability, aesthetic appeal, and corrosion resistance. Here are some common brass grades frequently used in CNC machining, each chosen for their unique properties and suitability for different applications:

C36000 Free-Cutting Brass, also known as free-machining brass, is the most commonly used brass alloy for machinable components due to its outstanding machinability and favorable mechanical properties. This alloy typically contains about 61.5% copper, 35.5% zinc, and small amounts of lead (around 3%), which contribute to its excellent machinability.

Key Properties:

- Excellent Machinability: The presence of lead in small quantities acts as a lubricant, significantly enhancing the alloy’s machinability, making it ideal for high-speed machining operations.

- Good Mechanical Strength: While it offers moderate strength, it is sufficient for most machining applications.

- Decent Corrosion Resistance: Offers resistance to corrosion from water and many atmospheric conditions.

Common Applications:

- Precision Components: Widely used for precision instruments such as gauges, clock components, and electronic hardware due to its ease of machining.

- Fittings and Connectors: Ideal for plumbing fittings, electrical connectors, and fasteners where extensive machining is required.

- Valves and Gears: Commonly used in the production of gears, valve components, and other mechanical parts that require detailed shaping.

- Decorative Items: Often utilized for decorative purposes in applications where a smooth, clean finish is desired.

C37700 Forging Brass, also commonly referred to as forging bronze, is a high-quality brass alloy particularly suited for hot forging and pressing. Composed primarily of copper and zinc, with a typical composition of around 58% copper, 39% zinc, and small amounts of lead (around 1.5% to 2.5%), it stands out for its excellent forgeability and good machinability.

Key Properties:

- Excellent Forgeability: The structure and composition of C37700 make it ideal for hot forging, allowing it to be shaped into complex forms without cracking.

- Good Machinability: While it offers superior forgeability, it also retains good machinability, making it suitable for subsequent machining operations.

- Decent Corrosion Resistance: Provides moderate resistance to corrosion, making it suitable for general use in mild environments.

Common Applications:

- Architectural Hardware: Used extensively in door handles, knobs, hinges, and other hardware where aesthetic appeal and mechanical performance are required.

- Plumbing Fittings: Ideal for applications such as faucet components and other plumbing fixtures that require a durable, aesthetically pleasing finish.

- Automotive Components: Applied in various automotive parts where strength and resistance to deformation are necessary during and after forming.

- Valves and Pumps: Commonly used for components in valves and pumps that can benefit from the alloy’s ability to be forged into complex shapes.

C38500 Architectural Bronze, commonly referred to as architectural brass, is a popular copper alloy primarily used for its aesthetic and mechanical properties. This alloy typically consists of approximately 57% copper, 40% zinc, and 3% lead, making it well-suited for extrusion and hot forming.

Key Properties:

- Excellent Formability: C38500 is highly malleable and can be easily formed or extruded into complex shapes, making it ideal for architectural applications.

- Good Machinability: Despite its high zinc content, the presence of lead improves its machinability, allowing for easier cutting and shaping.

- Attractive Appearance: Known for its rich, golden tone, it provides an aesthetically pleasing finish that enhances its use in decorative and architectural applications.

- Moderate Corrosion Resistance: It offers decent resistance to atmospheric corrosion, suitable for indoor and sheltered outdoor applications.

Common Applications:

- Decorative Architectural Elements: Widely used in the fabrication of decorative grilles, window frames, doors, and trims where both strength and appearance are crucial.

- Plaques and Signage: Ideal for creating detailed, durable plaques and signage that feature intricate designs due to its excellent formability.

- Railings and Fixtures: Employed in railings, fixtures, and other structural components in buildings, both for its mechanical properties and its visual appeal.

- Furniture and Hardware: Used in the production of furniture accents, knobs, and other hardware where a premium, decorative finish is desired.

C27000 Yellow Brass, often referred to simply as “Yellow Brass,” is a popular alloy in the brass family, primarily used where high ductility and visibly appealing surface finish are required. Composed typically of approximately 65% copper and 35% zinc, C27000 lacks the lead additives found in other machinable brasses, which influences its properties and applications.

Key Properties:

- High Ductility: This alloy is highly malleable, allowing it to be formed into complex shapes without cracking, making it ideal for deep drawing and forming operations.

- Good Corrosion Resistance: C27000 offers good resistance to corrosion from water and air, making it suitable for various environmental conditions.

- Excellent Cold Workability: It can be easily worked at room temperature, enhancing its suitability for intricate manual adjustments and cold forming.

- Moderate Machinability: While it does not machine as easily as leaded brasses, it still offers reasonable machinability and is often chosen for forming over machining.

Common Applications:

- Decorative Applications: Its bright, golden-yellow appearance makes it suitable for decorative items such as trim, fixtures, and architectural accents.

- Musical Instruments: Used in the manufacture of brass musical instruments like trumpets and trombones where both sound quality and aesthetics are important.

- Radiator Cores: Commonly used in the fabrication of radiator cores and tanks due to its excellent heat conductivity and resistance to rust.

- Cartridge Casings: Historically known as “cartridge brass” because of its use in ammunition casings where its ductility allows for effective reshaping and resizing.

Brass CNC Machining Processes

Brass Turning for Cylindrical Parts

Turning turns brass into precision cylindrical parts, ideal for applications requiring smooth surfaces and tight tolerances, such as shafts and bushings.

Brass Milling for Complex Features

Complex features including slots, contours and intricate geometries are machined into components to produce parts with unique shapes and fine features.

Brass Drilling for Holes

Drilling in brass machining focuses on producing accurate, clean holes, which is critical for parts that require precise hole sizes and locations, such as nozzles and connectors.

Surface Finishing for CNC Brass Parts

- Polishing: In order to make the surface of brass parts as smooth as a mirror, oxides and small surface imperfections can be removed.

- Plating: Nickel, chrome, gold plating

- Passivation: To remove surface contaminants and increase corrosion resistance.

- Powder Coating: Applying a protective and decorative layer that cures at high temperatures to form a skin.

- Anodizing: Improvement of surface hardness and wear resistance through a controlled oxidation process.

- Brushed: Brass is polished with a fine bristle brush on a belt or wheel to achieve a one-way satin finish.

- Bead blasting: brass is sprayed with small beads under high pressure to obtain a uniform matte finish.

- Engraving: Engraving patterns or text on the brass surface with a laser.

CNC Brass Parts We Offer

Explore our showcase of CNC machined brass parts, where precision meets craftsmanship. Our product display features a variety of components crafted from high-quality brass, each tailored to meet specific industry standards.

Connector Part

Choke Flange

Brass Flange

Connector Part

Brass Flange

Brass Parts

Module Body

Square Flange

4 Steps to Quickly Get Custom Brass Parts

1. Upload Files

Submit technical drawings (2D &3D) of the part with purchase quantities and material requirements, all files support NDA.

2. Quotation

Within 12 hours we will provide a manufacturability design analysis and an accurate quote.

3. Manufacturing

Once the design and materials have been selected, CNC machines machine the raw materials into the exact part required.

4. Delivery

Once all parts pass quality assurance, they are securely packaged and shipped to you via DHL/UPS.

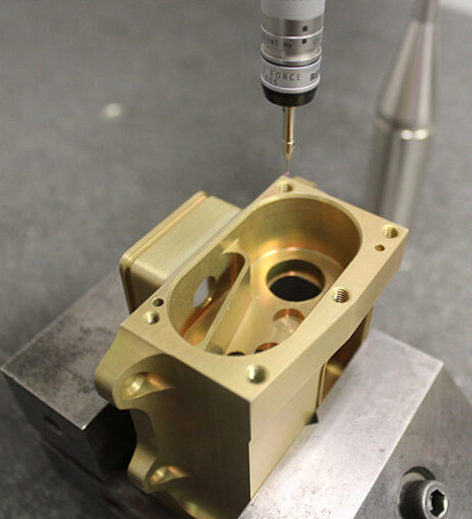

QUALITY INSPECTION

At RALLY, we hold every machining operation to exacting tolerances. Our factories are equipped with state-of-the-art inspection tools and precision measuring equipment to ensure top-notch quality control of all CNC machined parts. Parts are randomly inspected throughout the production process and fully evaluated by our quality assurance team upon completion.

Our comprehensive quality assurance protocols include the use of Coordinate Measuring Machines (CMMs), Optical Comparators and Surface Roughness Testers. In addition, all tools, equipment and components are calibrated and documented according to ISO 9001:2015 standards.

Why Use Our Brass Machining Service

Perfect Precision

Offering 3, 4, and 5-axis CNC machining with tight tolerances up to ±0.01mm.

Free Samples

Provide free samples before mass production to ensure that your requirements are met.

Fast Turnaround

Sample production in 3-5 days, with bulk orders completed within 10-20 days.

Extensive Material Options

Capable of machining in over 100+ different metal and plastic materials.

Unlimited Capabilities

No restrictions on the size, speed, or complexity of parts.

Proven Experience

More than 20 years in the industry, with CNC operators averaging 10 years of expertise.

CNC Machining Brass FAQs

How to CNC Brass ?

CNC (Computer Numerical Control) machining of brass involves programming a CNC machine to cut and shape the brass material into desired parts. The process starts with designing the part using CAD (Computer-Aided Design) software, which is then translated into a CNC-compatible file format. The brass is securely fixed on the machine table, and various tools such as drills, mills, and lathes are used to shape the material according to the design.

What is the machining process for brass?

The machining process of brass usually includes operations such as turning, milling, drilling and tapping. These operations are performed using CNC machines with high precision and efficiency. Brass can be machined at high speeds with excellent surface finishes.

Is brass easier to machine than aluminum?

Yes, brass is generally easier to machine than aluminum. It produces less friction and is less sticky during machining operations, which results in smoother finishes and longer tool life. However, brass is denser than aluminum, which may affect the machining speed and tool wear under certain conditions.

What types of brass are best for CNC machining?

The most commonly used brass types for CNC machining are 360 Brass, which is known for its high strength and excellent machinability, and 260 Brass, which is suitable for applications requiring good corrosion resistance. The choice of brass type depends on the specific requirements of the application, such as strength, corrosion resistance, and electrical conductivity.

What industries commonly use CNC machined brass parts?

Industries that commonly use CNC machined brass parts include electrical, automotive, marine, plumbing, and consumer electronics.

How do you ensure quality in brass CNC machining?

Quality in brass CNC machining is ensured through rigorous inspection processes, including dimensional checks, surface finish examination, and material property testing. Using precision CNC equipment and adhering to tight tolerances also helps maintain high quality in the machined parts.

How does the choice of brass alloy impact the final product?

The choice of brass alloy impacts the final product’s strength, corrosion resistance, electrical conductivity, and appearance. Different alloys are selected based on the specific requirements of the application, ensuring that the final product performs well under the intended operating conditions.

What is the lead time for brass CNC machined parts?

The lead time for brass CNC machined parts can vary depending on the complexity of the parts, the quantity ordered, and the capacity of the machining facility. Typically, lead times can range from a few days for simple parts to several weeks for more complex or large-volume orders.

Work with RALLY for CNC Machined Brass Parts

Request a quote for brass CNC machining today! No minimum order quantity and free samples available!