The growing demand for higher-quality, performance-driven bicycles has inevitably shifted the manufacturing landscape of the cycling industry. A key player in this revolution is Computer Numerical Control (CNC) machining – a method renowned for its precision, versatility, and ability to create intricate designs from a variety of materials.

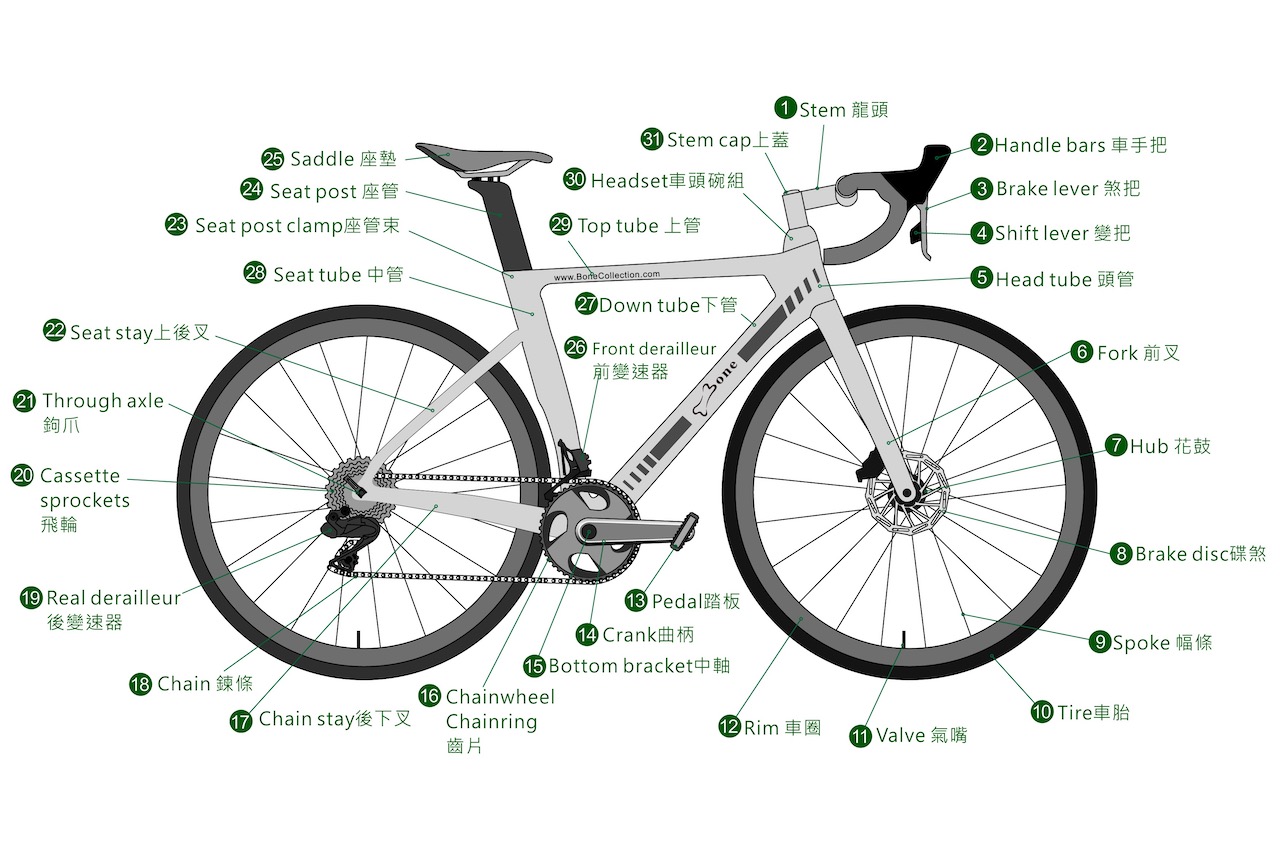

CNC machine tools can make a variety of bicycle parts, including but not limited to:

Frame

Bicycle frames are the backbone of any bike. They're essential for holding all the components together and keeping the rider upright. CNC machining, with its precision and versatility, allows manufacturers to craft frames from materials like aluminum, steel, or titanium with exactitude. The process enables a high level of customization, creating lighter, sturdier, and more aerodynamic frames that cater to specific rider preferences and needs.

Cranksets

Cranksets play a crucial role in converting the cyclist's pedaling action into the movement of the bike. A crankset typically consists of one or more chainrings (sprockets) and the cranks. By leveraging CNC machining, manufacturers can produce lighter, stiffer, and stronger cranksets, which significantly improves the efficiency of power transfer.

Bicycle Hubs

Hubs are the center part of the wheels, housing the axle and the bearings that allow the wheel to spin freely. CNC machining is often used in the production of hubs, particularly high-performance models, due to the need for precision in these components. CNC-machined hubs typically have a superior finish, more accurate alignment, and better bearing seats, leading to smoother rides and longer component life.

Bicycle Stem

Bicycle stems, connecting the handlebars to the bike's fork, benefit from CNC machining. This technique crafts highly precise, strong, and lightweight stems, influencing bike handling and rider comfort. The process accommodates unique design features and specific rider needs, significantly elevating the bicycle's performance and aesthetic appeal.

Bike Chain Ring

CNC machining significantly improves the manufacture of bicycle gears and chains. By offering unparalleled precision, it ensures gears mesh smoothly for efficient power transfer, and chains fit perfectly on sprockets. This results in higher durability, reduced maintenance, and improved overall ride quality, making CNC-machined gears and chains a top choice for performance bicycles.

Pedals

CNC-machined pedals provide a blend of strength, low weight, and intricate design that's hard to match. They can be crafted for specific types of cycling, such as downhill racing or long-distance touring, to meet unique demands for grip, durability, and comfort.

Seat and seat post

CNC machining revolutionizes bicycle manufacturing, particularly in creating seat posts and seats. It allows for high-precision crafting of seat posts, balancing optimal strength and weight, and excelling in complex designs like dropper posts. Moreover, it's utilized in making saddle shells and rails, ensuring these components are strong, flexible, and shock-absorbent, thereby elevating the rider's comfort and biking performance.

Brake components

These components are directly related to the safety of the bicycle and require precise size and shape as well as high strength and wear resistance.

Guidance systems

such as forks and head tubes, these parts affect the bicycle's steering performance and require precise size and shape.

These are some of the common bicycle parts made with CNC machines. However, with proper design, CNC machine tools can make basically any shape and size of bicycle parts.

Benefits of CNC Machining in Bicycle Manufacturing

CNC machining offers unparalleled precision, making it possible to manufacture complex and high-performance parts that may be difficult, if not impossible, to create using other methods. The ability to reproduce designs flawlessly allows for mass production without quality loss. Furthermore, CNC machining minimizes material waste. Raw material optimization reduces costs and environmental impacts, making it an excellent choice for sustainable manufacturing practices.

Challenges and the Future

While CNC machining offers several advantages, it's not without its challenges. The initial setup costs for CNC machines can be quite high, and the process can be time-consuming for complex designs. However, with the advent of advanced software and AI capabilities, CNC machining's efficiency and accuracy continue to improve. Combined with the increasing demand for high-performance and customized bicycles, CNC machining will undoubtedly play an integral role in the future of bicycle